Table of Content =

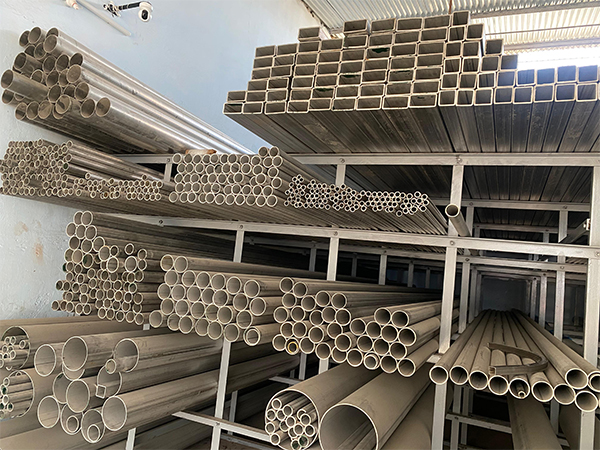

One of the most common stainless steel alloys, the 316 grade, is used to make stainless steel pipes and tubes, or SS 316. Because of its exceptional resistance to corrosion, stainless steel 316 can be used in both commercial and domestic settings for a wide range of purposes. With 8% nickel and 18% chromium, the alloy offers a nice mix of formability, strength, and oxidation resistance. Because of its resilience to abrasive conditions and preservation of structural integrity, stainless steel 316 pipes and tubes find widespread application in the food and beverage, pharmaceutical, and chemical processing sectors. These pipes and tubes are also easily produced into various shapes and sizes and have good weldability, which makes them a versatile option for a variety of engineering and construction tasks.

Pipe Specifications: ASTM A312, A358 / ASME SA312, SA358

Tube Specifications: ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554

Dimensions: ANSI B36.19, ANSI B36.10

Pipe Outside Diameter: 6.00 mm OD up to 914.4 mm OD, Sizes up to 24" NB available Ex-stock, OD Size Steel Tubes available Ex-stock

Tube Outside Diameter: 1/8" OD TO 2"OD 3MM OD TO 38 MM OD

Thickness Range: 1MM TO 3 MM 0.028 TO 0.156 IN, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS

Type: Seamless / ERW / Welded / Capillary Tubes

Form: Round Tube, Square Tube, Rectangular Tube

Length: Single Random, Double Random & Required Length

End: Plain End, Beveled End, Treaded

End Protection: Plastic Caps

Finish: Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

External Coating: 3LPE / 3LPP/ FBE/ DFBE/ PP

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| SS 316 | S31600 | 1.4301 | Z7CN18‐09 | X5CrNi18-10 | SUS 316 | 316S31 | 08Х18Н10 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| 316 | 0.08 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0-20.0 | - | 8.0-10.5 | 0.10 |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316 | 515 | 205 | 40 | 92 | 201 |

Seamless TP 316 stainless steel pipes are well-known for their robustness, ability to withstand corrosion, and visual appeal. TP 316, a popular alloy in the 300 family, is made of premium stainless steel and is renowned for its outstanding resistance to oxidation and a wide variety of chemicals. Because these pipes can endure harsh environments and retain their structural integrity, they are frequently employed in sectors including chemical processing, food & beverage, and pharmaceuticals. Compared to welded pipes, their seamless design increases strength and dependability, which makes them perfect for high-pressure applications.

Many suppliers of Stainless Steel 316 Electropolish Pipe , renowned for their excellent quality and dependable service, are based in India. The outstanding corrosion resistance, durability, and versatility of Stainless Steel 316 Electropolish Pipe , which are widely regarded in a variety of industrial applications, are offered by these suppliers in a wide range. One of the most widely used grades of stainless steel is SS 316, which is prized for its exceptional qualities and is perfect for usage in petrochemical, food processing, pharmaceutical, and construction industries. Indian suppliers make sure their goods adhere to global norms and specifications, offering premium materials to both local and foreign customers.

| Ahmedabad | Surat | Vadodara | Rajkot | Bhavnagar | Jamnagar |

| Junagadh | Gandhinagar | Anand | Gandhidham | Navsari | Morbi |

| Nadiad | Surendranagar | Bharuch | Mehsana | Bhuj | Porbandar |

| Palanpur | Valsad | Vapi | Gondal | Veraval | Godhra |

| Patan | Kalol | Dahod | Botad | Amreli | Deesa |

Bolts, screws, nuts, and other fasteners made of stainless steel that offer excellent corrosion resistance and endurance in a variety of settings are known as Stainless Steel 316 Electropolish Pipe .

The stainless steel grades 316 and 316 are the most often used. Better corrosion resistance is seen in grade 316, particularly in chemical and marine conditions.

Because of their durability, strength, and resistance to corrosion, Stainless Steel 316 Electropolish Pipe are the preferred choice for outdoor, maritime, and high-moisture settings.

Yes, but in order to stop galvanic corrosion between the two metals, a barrier such as a coating or washer is advised.

Stainless Steel 316 Electropolish Pipe are typically non-magnetic, but some grades, like 410, can be slightly magnetic.

Owned & Powered by : : #1 Vinayak InfoSoft - SEO Company Ahmedabad :: Disclaimer